Acura Brake Caliper 45019S5DL00RM

Address

No.2 Building of Jiujie zone, Kunyang Town,Pingyang County, Wenzhou City, Zhejiang

Phone

+86 18857856585

+86 15088970715

Hours

Monday-Sunday: 9am to 12pm

Product Description

Interchanges No.

| ER1674KB ABSCO |

| 18FR2078 AC-DELCO |

| SLB19729 AUTOLINE |

| 99-00942B BBB INDUSTRIES |

| SC1820 CAN USE NUMBER |

| 19-B2659 |

| 19B2659 |

| SLC9533 FENCO |

| BC182659 MPA |

| 242-64186 NAPA / RAYLOC |

| 10-05273-1 PROMECANIX |

| SC1819A DNS |

Compatible Applications

| Acura EL 2001-2005 Front Left |

| Honda Civic 2001-2005 Front Left |

Assembling:

1. Install the brake disc and brake pads if necessary.

2. Install the new brake caliper and tighten bolts to the specified torque.

3. Tighten the brake hose and then remove the pressure from the brake pedal

4. Make sure that all movable parts are lubricated and glide easily.

5. Re-connect the pad wear sensor wires if fitted.

6. Bleed the brake system by following the vehicle manufacturer’s guidelines.

7. Mount the wheels.

8. Tighten the wheel bolt/nuts with a torque wrench to the correct torque settings.

9. Check the brake fluid and replenish if necessary. Follow the operating instructions.

10. Check that there is no leakage of brake fluid.

11. Test the brakes on a brake test stand and carry out a test run.

What You Can Get from Our Factory

BIT’s main business is the development and manufacturing of automotive brake-related products. As an independent brake specialized manufacturer, we develop and manufacture functional components such as brake calipers and accessories.

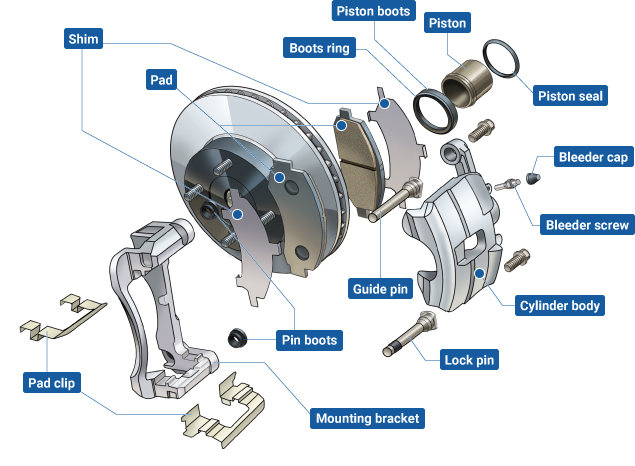

We have complete parts for disc brakes, such as brake caliper, bracket, piston, seal, bleeder screw, bleeder cap, guide pin, pin boots, pad clip and so on. Anything in the disc brakes, welcome to contact us to get the catalog.

By the way, we also have wide range catalogs for European, American, Japanese and Korean cars. Such as Audi, VW, BMW, Dodge, Chevy, Toyota, honda, KIA, Hyundai and so on. Find something what you want in our company.

What is Our Production

We are a professional manufacturer of braking system. We have our own R & D and production team. Each product will be tested after production and tested again before delivery.

How disc brakes work

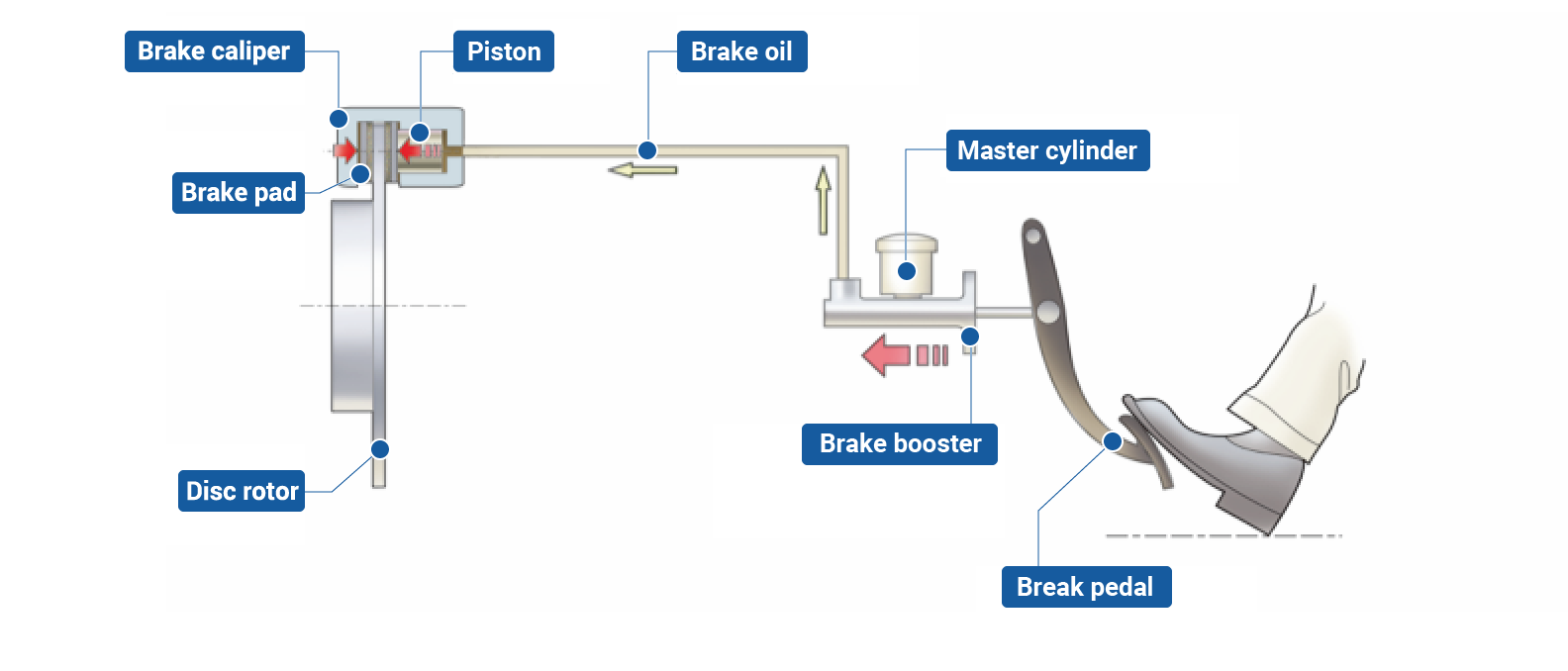

When the driver steps on the brake pedal, the power is amplified by the brake booster (servo system) and changed into a hydraulic pressure (oil-pressure) by the master cylinder. The pressure reaches the brakes on the wheels via tubing filled with brake oil (brake fluid). The delivered pressure pushes the pistons on the brakes of the four wheels. The pistons in turn press the brake pads, which are friction material, against the brake rotors which rotate with the wheels. The pads clamp on the rotors from both sides and decelerate the wheels, thereby slowing down and stopping the vehicle.

Certificate

Quality and value is a common goal we share as a company. We are committed to face any challenges and see this as an opportunity to offer more novel solutions.

This led to many firsts in automotive innovations, as well as many design patents based on the futuristic approach. As a manufacturer of brake calipers, you can rely on us to bring a revolutionary brake caliper product line. With the following advantages, you can be confident that you are getting the best and finest service in the market. In order to assure you our quality, we approved the IATF 16949 Certificate in 2016.